Cast WC Tubular Rod

Cast WC Tubular Rod

Cast WC Tubular Rod Tubular High Hardness Surfacing Welding Rods Cast Tungsten Carbide Rod For Hardfacings

Properties: Good wear resistance

Application: Mining industry,Civil construction,Agriculture。

Cast Tungsten Carbide is a powder of irregular dark-gray granule with high melting point,high hardness and high wear resistance. Adopted high temperature melting, crushing process.

Due to its special characters, the products are widely used in mining, oil, metallurgical industry, steel, construction machinery and other industries which applied in the pre-reinforcement of wear-resistant surface and repairing for easily worn parts.

Such as: PDC bit, petroleum drill pipe, TC bearing, etc.

|

W |

Total carbon |

Free carbon |

Chlorinated residues |

Fe |

Cr |

V |

Ti,Ta,Nb |

Other impurities(Co,Ni,Mo,etc.) |

|

95-96 |

3.9±0.1 |

0.08 |

0.1 |

0.5 |

0.2 |

0.2 |

0.2 |

0.1 |

|

Hardness(HRA) |

93~93.7 |

|

Micro hardness(kg/mm²) |

2500-3000 |

|

TRS( kg/mm²) |

48.2 |

|

Density( g/cm³) |

16.5 |

|

Melting Point℃ |

2525 |

|

Relative wear resistance with that of YG6 as 1 |

3.46~4.10 |

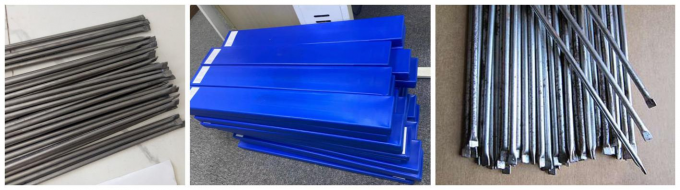

Normal Package or Pack of Tubular Cast Tungsten Carbide Welding Rod According to Customers' requirement

Cast tungsten carbide as a wear resistant strengthening material has a wide range of applications and these mainly are:

1.Mining industry: Build-up welding of parts of rock crushers, auger tips,twist drills, scraping plates of scrapers, teeth's coronas of drilling tools, fishtail drills, teeth of tricone bits and support claws of tricone bits, etc.

2.Civil construction: the edges of shovelling buckets, parts of bulldozers,scraping plates, parts of earth agitators, clawer belts of tractors, etc.

3.Agriculture: for columnar teeth of threshers, edges of drills, ploughs, teeth of shovels,etc.

4.Architecture: for spiral crushers for cement, cement loaders, bick scrapers, cutters, earth mixing machines, kiln digging shovels, etc.

5.Miscellaneous:Build-up welding can be used in industries of steel, machinery, sugar, wood, papermarking and on hammers for crushing coal in power plants, etc.Substantially increasing the lifeti-me of parts and components.

|

Grade |

Spec. |

Fillings characters |

Application |

|

WLRC-1 |

Φ3.2X600 |

60-80 mesh |

Metallurgy, construction,Grain and oil processing, road construction,Surfacing welding of workpiece surface in mining machinery industry,petroleum,Surfacing of geological tools |

|

WLRC-2 |

Φ4.0x600 |

||

|

WLRC-3 |

Φ5.0x600 |

||

|

WLRCS-1 |

Φ3.2x600 |

Compound materials like sinterde tungsten carbide,superhard tungsten carbide etc. |

Especially suitable for surfacing of petroleum and natural gas geological tools, with excellent wear resistance and impact resistance, high comprehensive performance |

|

WLRCS-2 |

Φ4.0x600 |

||

|

WLRCS-3 |

Φ5.0x600 |

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.png?x-oss-process=image/resize,w_100/quality,q_100)