Hastelloy G-30

Hastelloy G-30

Hastelloy G-30 UNS N06030 High Temperature Alloys nuclear waste processing pickling operations

HASTELLOY G-30 is an improved version of nickel-chromium-iron molybdenum-copper alloy G-3. With higher chromium, added cobalt and tungsten the nickel HASTELLOY G-30 shows superior corrosion resistance over most other nickel and iron based alloys in commercial phosphoric acids as well as complex environments containing highly oxidizing acids such as nitric/hydrochloric, nitric/hydrofluoric and sulfuric acids. HASTELLOY G-30 resists the formation of grain boundary precipitates in the heat-affected zone, making it suitable in the as-welded condition.

|

GB |

UNS |

DIN |

W-Nr |

|

GH3404 |

N06030 |

NiCr30FeMo |

2.4603 |

Chemical processing involving phosphoric acid, sulfuric acid and nitric acid; nuclear fuel reprocessing; nuclear waste processing; pickling operations; petrochemical; fertilizer manufacture; pesticide manufacture; and gold ore extraction.

|

% |

Ni |

Mo |

Cr |

W |

Fe |

Mn |

C |

Si |

P |

S |

Cu |

Nb+Ta |

|

Min |

Bal |

4.0 |

28.0 |

1.5 |

13.0 |

|

|

|

|

|

1.0 |

0.3 |

|

Max |

6.0 |

31.5 |

4.0 |

17.0 |

1.5 |

0.03 |

0.8 |

0.04 |

0.02 |

2.4 |

1.5 |

|

Grade |

Density |

Melting Point |

Tensile strength,MPa |

Yield strength,MPa |

Elongation,% |

|

Hastelloy G-30 |

8.22g/cm3 |

1360-1410°C |

807-841 |

379-427 |

44-48 |

Hastelloy G-30 is a high chromium nickel-base alloy which has superior corrosion resistance over most other nickel and iron-base alloys in commercial phosphoric acid as well as many complex environments containing highly oxidizing acids such as nitric/hydrochloric, nitric/hydrofluoric and siHfuric acids. It resists the formation of grain boundary precipitates in the heat-affected zone, making it suitable for use in most chemical process environments in the as-welded condition.

|

Rod, Bar |

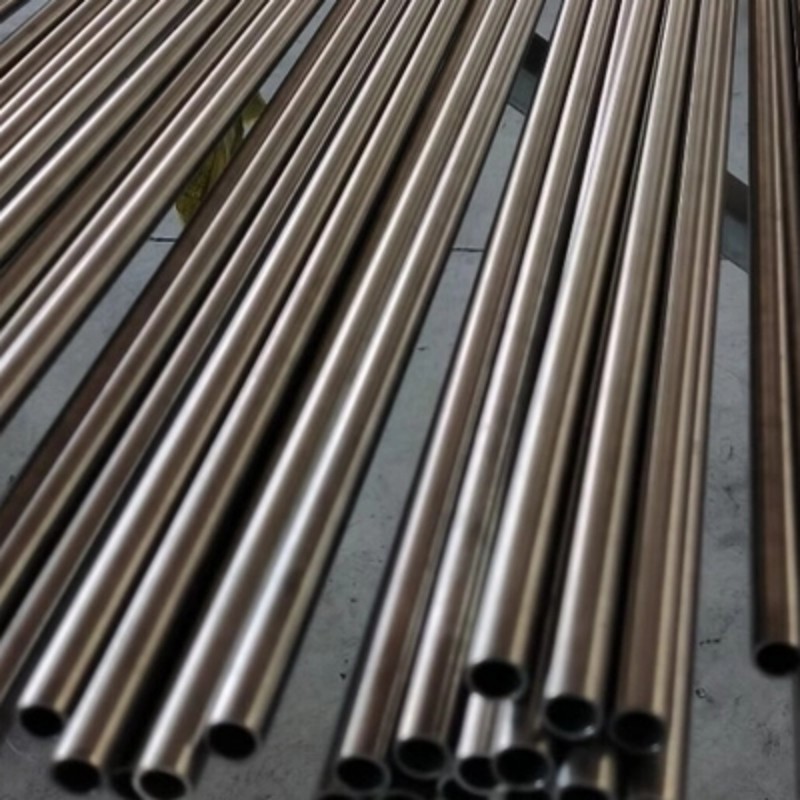

Pipe, Tube |

Plate, Sheet, Strip |

Pipe fittings |

Forgings |

Wire |

|

ASTM B574 |

ASTM B622, B619 |

ASTM B575 |

ASTM B366 |

ASTM B564 |

DIN 17753 |

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)