Incoloy 020

Incoloy 020

Incoloy 020 UNS N08020 GH 1015 High Temperature Alloys Bulletproof fiber and aramid manufacturing process equipment

INCOLOY® alloy 020 (UNS N08020) has excellent corrosion resistance in chemical environments containing sulfuric acid, and useful resistance to environments containing chlorides, nitric acid, and phosphoric acid. Other uses include the production of gasoline, solvents, explosives, inorganic and organic chemicals, pharmaceuticals, and food and synthetic materials. INCOLOY alloy 020 is readily fabricated to produce mixing tanks, heat exchangers, process piping, pickling equipment, pumps, valves, fasteners and fittings. Applications for alloy 020 requiring resistance to aqueous corrosion are essentially the same as those for INCOLOY alloy 825.

|

UNS |

GB |

W-Nr. |

NS |

|

N08020 |

GH1015 |

2.4660 |

NS143 |

- Storage tanks, agitators, pump and valve parts, fasteners, and accessories

- Heat exchangers, mixing tanks, metal cleaning, and pickling equipment, and pipelines

- Synthetic rubber, plastic, synthetic fiber manufacturing equipment

- Chemical process pipelines, reactor vessels

- Bulletproof fiber and aramid manufacturing process equipment

- SO2 scrubber and other harsh environments

|

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

P |

S |

Nb+Ta |

Mo |

Cu |

|

Min |

32.0 |

19.0 |

Rest |

|

|

|

|

|

8xC |

2.0 |

3.0 |

|

Max |

38.0 |

21.0 |

0.07 |

2.0 |

1.0 |

0.045 |

0.035 |

1.0 |

3.0 |

4.0 |

|

Grade |

Density |

Tensile strength,MPa |

Yield strength,MPa |

Elongation,% |

|

Incoloy 020 |

8.08g/cm3 |

620 |

300 |

40 |

- Excellent resistance to chloride stress corrosion cracking

- Excellent mechanical properties and processability

- Minimal carbide precipitation during welding, resistance to intergranular corrosion

- Excellent corrosion resistance to sulfuric acid of various concentrations and temperatures

- Good oxidation resistance in environments containing a lot of sulfuric acids, nitric acid, and phosphoric acid

- Excellent stability to the sensitization process

- Resistant to harsh environments, pitting and crevice corrosion

|

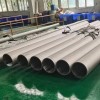

Seamless Pipe & Tub |

Welded Pipe, Tube, Fittings |

Electric Fusion Welded Pipe |

Flange and Forged Fittings |

Billets and Bars, Wire |

Round Weaving Wire |

Plate, Sheet and Strip |

|

ASTM B829 |

ASTM B464 |

ASTM B751 |

ASTM B462 |

ASTM B472 |

ASTM B475 |

ASTM B463 |

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)