WL Colmonoy 6

WL Colmonoy 6

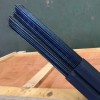

Colmonoy 6 Welding Rod - Nickel Based Alloy Hard Facing Rod Die Pressure Valves Corrosion Resistant Coating

Properties: High hardness, good wear resistance and corrosion resistance

Application: Automotive, Wood&Timber, Chemical&Petrochemical, Power Generation, Oil&Gas

WL-NiCrBSi 60 is a hard nickel based alloy with excellent wear resistance, high temperature hardness, and corrosion re-sistance. It is available in rod and powder forms, giving abrasion and corrosion resistant deposits, which can be ground, but is not machinable. NiCrBSi 60 has a very dense corrosion resistant coating with superior fusing characteristics. Fusion of the coating may be achieved by oxy-fuel torch, induction heating or by furnace fusion.

NiCrBSi 60 can be applied by PTA welding, laser cladding, spray-fuse, powder-weld, plasma spray and HVOF pro-cesses.

Hardness: 57-62HRC

|

C |

Si |

B |

Mo |

Cr |

W |

Ni |

Fe |

|

0.7 |

4.0 |

3.2 |

/ |

16 |

/ |

Rest |

<5.0 |

|

AWS / ASME: A5.21 / SFA5.21 ERNiCr-C |

|

|

Cold / Hot Abrasion |

Excellent / Good |

|

Erosion / Corrosion |

Good / Good |

|

Impact |

Fair |

|

Magnetic |

No |

|

Deposit Layers |

2 Max |

|

Machinability |

Grinding |

|

Max. Operating Temp. |

600 ºC |

For length 350mm 500mm pack in carton each 5kg

For 1000mm packing in 5kg tube, 4 tubes in one 20kg carton

For length more than 1000mm, pack in wooden box directly

Automotive

Wood&Timber

Chemical&Petrochemical

Power Generation

Oil&Gas

Mining

Plastic&Rubber

Pulp&Paper

Dies&Molds

|

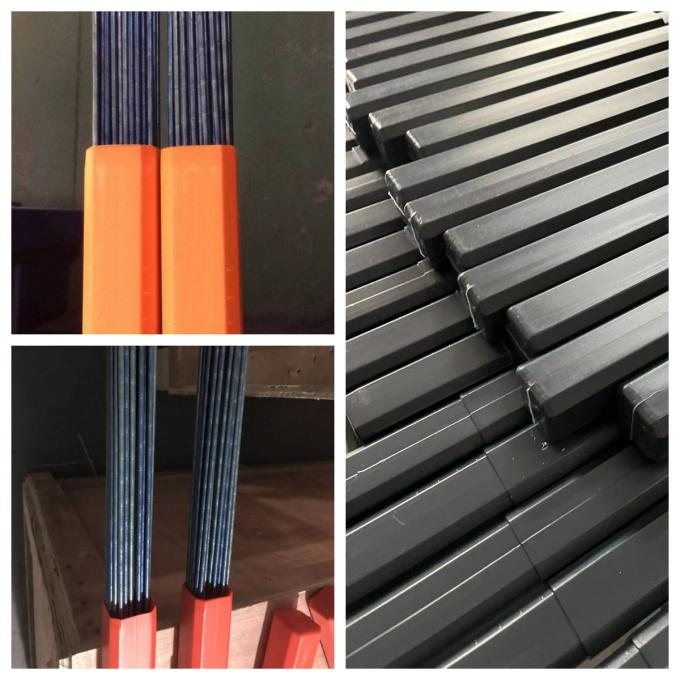

Trademark |

Nominal Chemical Composition |

HRC |

Application |

|||||||||

|

C |

Cr |

Si |

W |

Ni |

Fe |

Mn |

Mo |

Co |

B |

|||

|

WL Co1 |

2.45 |

30.0 |

1.0 |

13.0 |

≤3.0 |

≤3.0 |

≤1.0 |

≤1.0 |

Bal. |

|

50-58 |

Valve seat insets, bearing, sawteeth, rotary ring, Pump Sleeves |

|

WL Co3 |

2.4 |

30.5 |

1.0 |

13.0 |

≤3.0 |

≤3.0 |

≤1.0 |

≤1.0 |

Bal. |

|

50-56 |

Valve seat insets,steel mill guide roll, wearing panel of cracker blade, etc. |

|

WL Co4 |

1.0 |

31.0 |

1.0 |

14.0 |

≤3.0 |

≤1.0 |

≤0.5 |

≤0.5 |

Bal. |

|

45-50 |

Hot extrusion die, dry battery industry |

|

WL Co6 |

1.2 |

29.0 |

1.0 |

4.5 |

≤3.0 |

≤3.0 |

≤1.0 |

≤1.0 |

Bal. |

|

40-46 |

Engine valve, high temperature valve, turbine blade |

|

WL Co12 |

1.4 |

30.0 |

1.3 |

8.5 |

≤3.0 |

≤3.0 |

≤1.0 |

≤1.0 |

Bal. |

|

44-50 |

Pressure valves, sawteeth screw fights |

|

WL Co20 |

2.5 |

32.0 |

1.0 |

17.0 |

≤3.0 |

≤3.0 |

≤0.5 |

≤1.0 |

Bal. |

|

54-59 |

Wear plate, bearing sleeve, etc. |

|

WL Co21 |

0.2 |

27.0 |

1.0 |

0.2 |

≤3.0 |

≤2 |

≤1.0 |

≤5.5 |

Bal. |

|

20-40 |

Fluid valve seat, turbine blades, hot forging die |

|

WL Co25 |

0.05 |

20.0 |

1.0 |

15.0 |

10.0 |

≤2.0 |

≤1.5 |

≤1.0 |

Bal. |

|

24 |

High temperature and corrosion-resistant valve sealing surface, pressure casting dies, etc. |

|

WL Co31 |

0.5 |

26.0 |

1.0 |

7.5 |

10.0 |

≤3.0 |

≤1.0 |

≤1.0 |

Bal. |

|

30-35 |

Extrusion die, steam turbine blade, etc. |

|

WL Co32 |

1.8 |

26.0 |

1.2 |

12.0 |

22.0 |

≤1.5 |

≤0.5 |

≤1.0 |

Bal. |

|

40-45 |

Engine inlet and exhaust valve |

|

WL Co190 |

3.2 |

26.0 |

1.0 |

14.0 |

≤1.0 |

≤3.0 |

≤1.0 |

≤1.0 |

Bal. |

|

54-60 |

Petroleum drill bit, mining industry |

|

WL CoT400 |

0.08 |

8.5 |

2.6 |

|

1.5 |

≤1.5 |

≤1.0 |

28 |

Bal. |

0.8 |

50-60 |

Valve and roller path, plastic extruder in strongly corrosive |

|

WL CoT800 |

0.08 |

18.0 |

3.4 |

|

≤1.5 |

1.5 |

≤1.0 |

28 |

Bal. |

0.8 |

52-58 |

Valve and roller path, plastic extruder in strongly corrosive |

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.png?x-oss-process=image/resize,w_100/quality,q_100)