WL ERNi-1

WL ERNi-1

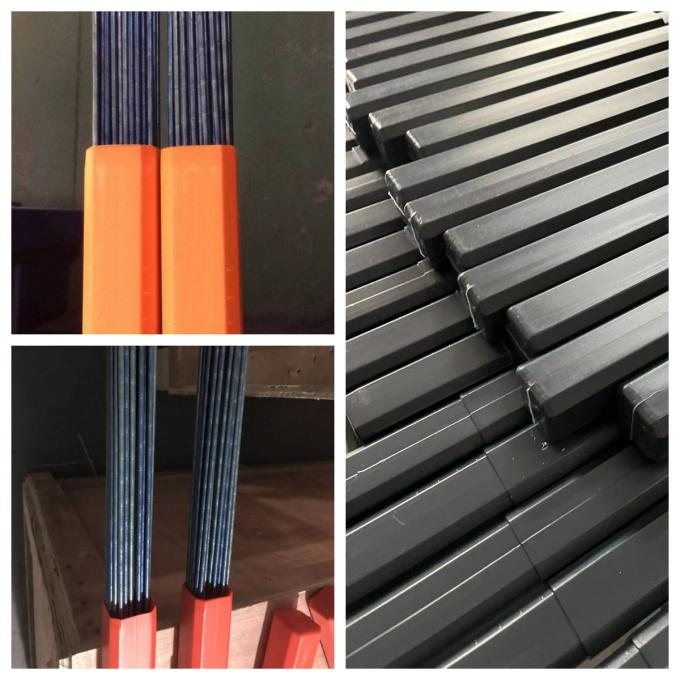

WL ERNi-1 Welding Rod - Nickel Based Alloy Hard Facing Rod nickel 200 or 201 Trays, baskets, and fixtures are utilized in various heat treatments

Properties: Corrosion resistance

Application: Refractory anchors, strand annealing and radiant tubes, high-velocity gas burners, etc.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

WL ERNi-1 is intended for welding wrought and cast forms of commercially pure nickel (ASTM B160, B161, B162, and B163) with the gas tungsten arc, gas metal arc, and plasma arc welding processes. The weld metal has good corrosion resistance, particularly in alkalis. ERNi-1 is well suited for dissimilar welding, including the joining of Nickel 200 and 201 to stainless steel. It can also be used for joining carbon steels to copper-nickel alloys.

|

Ni |

C |

Mn |

Fe |

P |

S |

Si |

Cu |

Al |

Ti |

Other |

|

|

min |

93.0 |

|

|

|

|

|

|

|

|

2.0 |

|

|

max |

|

0.15 |

1.0 |

1.0 |

0.03 |

0.015 |

0.75 |

0.25 |

1.5 |

3.5 |

0.5 |

AWS A5.14 ERNi-1 / ASME SFA 5.14 ERNi-1 / UNS NO2061 / ASME IXF-41

For length 350mm 500mm pack in carton each 5kg

For 1000mm packing in 5kg tube, 4 tubes in one 20kg carton

For length more than 1000mm, pack in wooden box directly

• Trays, baskets, and fixtures are utilized in various heat treatments such as carburizing and carbon nitriding.

• Refractory anchors, strand annealing and radiant tubes, high-velocity gas burners, etc.

• Insulating cans in ammonia reformers and catalyst support grids utilized in the nitric acid manufacturing process.

Matching nickel base alloy: NO2200, NO2201, 2.4060, 2.4061, 2.4066,2.4068.

Dissimilar welds: nickel alloys to low alloy/CrMo/stainless steel.

Cladding: surfacing a wide range of steels, and also as a buffer layer.

Cast iron: can prove useful on a range of cast irons.

• For welding of nickel 200 or 201.

• Also for overlay on steel as well as repairing cast iron castings.

• It can also be used for dissimilar joints between nickel or nickel alloys to stainless or ferritic steels.

•Has good corrosion resistance particularly in alkalis.

|

Tensile Strength |

Yield Strength |

Elongation |

|

66000psi |

38000psi |

28% |

.jpg?x-oss-process=image/resize)

.jpg)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.png?x-oss-process=image/resize,w_100/quality,q_100)