WL ERNiCrMo-3

WL ERNiCrMo-3

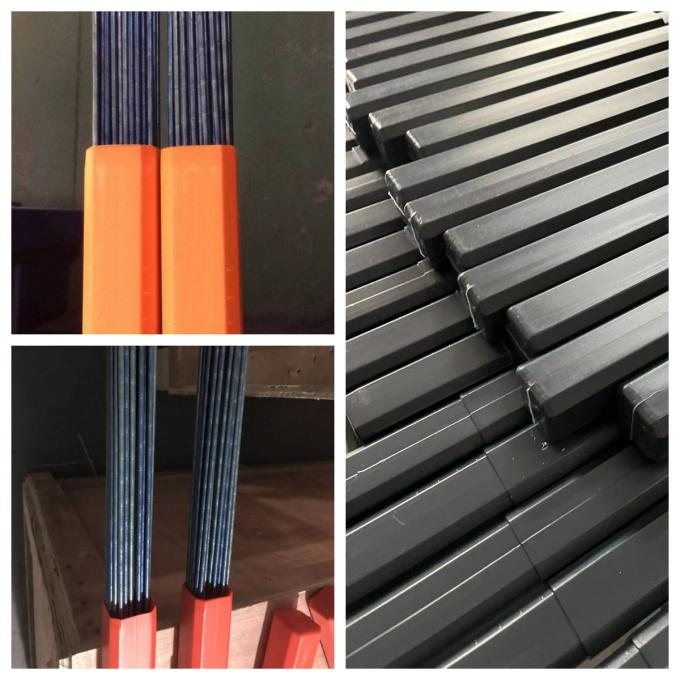

WL ERNiCrMo-3 Welding Rod - Nickel Based Alloy Hard Facing Rod pollution control equipment, marine equipment

Properties: good stress, pitting and crevice corrosion resistance

Application: the chemical processing industry, pollution control equipment, marine equipment, nuclear reactor components, pump shafts.

ERNiCrMo-3 is a nickel-chromium-molybdenum filler metal used for MIG, TIG, submerged arc and plasma arc welding of Inconel alloys 601, 625 and 690 as well as Incoloy alloys 800, 825 and 800HT to themselves or to each other. Filler Metal Alloy 625 is excellent for joining these Inconel and Incoloy alloys to dissimilar metals such as carbon steel, low alloy steel, ferritic and austenitic stainless steels. This filler metal produces weld deposits with excel lent corrosion and oxidation resistance against phosphoric acids, organic acids and seawater. Good resistance against pitting and stress corrosion cracking in chloride containing environments. The weld deposits exhibit high strength and fatigue resistance over a broad range of temperatures ranging from cryogenic up to 1800°F.

|

Ni+Co |

C |

P |

Fe |

Mn |

S |

Si |

Cu |

Al |

Ti |

Mo |

Cr |

Nb+Ta |

Other |

|

|

min |

58 |

|

|

|

|

|

|

|

|

|

8.0 |

20 |

3.15 |

|

|

max |

|

0.1 |

0.02 |

3.0 |

0.5 |

0.015 |

0.5 |

0.5 |

0.4 |

0.4 |

10.0 |

23 |

4.15 |

0.5 |

AWS/ASME Spec 5.14 ; AWS Class ERNiCrMo-3 ; UNS N06625 ; ABS Approved

For length 350mm 500mm pack in carton each 5kg

For 1000mm packing in 5kg tube, 4 tubes in one 20kg carton

For length more than 1000mm, pack in wooden box directly

Nickel Alloy Filler Metal 625 is most commonly used in the chemical processing industry, pollution control equipment, marine equipment, nuclear reactor components, pump shafts.

• Contains low iron (Fe less than 1%) and is used for welding of nickel-chromium-molybdenum alloys.

• Also for cladding and welding dissimilar base metals such as Ni-Cr-Mo alloys to stainless and carbon steels.

• The Ni-Cr-Mo alloy system provides excellent resistance to oxidizing and reducing environments. The high molybdenum content provides good stress, pitting and crevice corrosion resistance.

|

Condition |

Tensile strength Mpa (Ksi) |

Yield strength Mpa (Ksi) |

Elongation % |

|

AWS Reaulrement |

760 (110) |

Not specified |

Not specified |

|

Typical Results as weled |

790 (115) |

590 (85) |

35.0 |

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.png?x-oss-process=image/resize,w_100/quality,q_100)