WL ERNiCrMo-4

WL ERNiCrMo-4

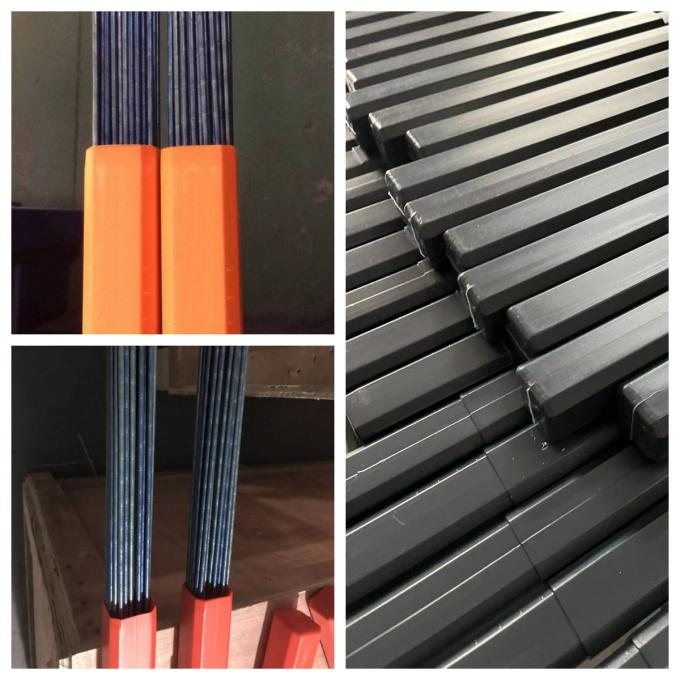

WL ERNiCrMo-4 Welding Rod - Nickel Based Alloy Hard Facing Rod chemical and petrochemical processing

Properties: Excellent corrosion resistance, high temperature performance and mechanical properties.

Application: chemical and petrochemical processing, oil and gas, power generation, pharmaceutical, pulp, paper production, and wastewater treatment.

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

C276 is a nickel-chromium-molybdenum filler metal developed for MIG and TIG welding of Hastelloy C and Hastelloy C-276 to themselves, to stainless steel or to other nickel base alloys. C276 offers excellent resistance to pitting, stress-corrosion cracking and oxidizing atmospheres up to 1900°F. This filler metal is frequently used for welding the clad side of joints on steel in the chemical, petrochemical and petroleum industries. C276 offers excellent resistance to a wide range of chemicals including the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide solutions. Other uses would include hot contaminated mineral acids, solvents, solutions (organic and inorganic) contaminated by chlorine or chlorides, dry chlorine acetic or ferric acids, seawater and brine solutions.

|

Ni |

C |

P |

Fe |

Mn |

S |

Si |

Cu |

Mo |

Co |

V |

Cr |

W |

Other |

|

|

min |

Rem |

|

|

4.0 |

|

|

|

|

15.0 |

|

|

14.5 |

3.0 |

|

|

max |

|

0.02 |

0.04 |

7.0 |

1 |

0.03 |

0.08 |

0.5 |

17.0 |

2.5 |

0.35 |

16.5 |

4.5 |

0.5 |

AWS A5.14 ERNiCrMo-4;ASME II SFA-5.14 ERNiCrMo-4 ; UNS N10276 ; SNi6276 (NiCr15Mo16Fe6W4)

For length 350mm 500mm pack in carton each 5kg

For 1000mm packing in 5kg tube, 4 tubes in one 20kg carton

For length more than 1000mm, pack in wooden box directly

These welded rods are recurrently used in many industries, including chemical and petrochemical processing, oil and gas, power generation, pharmaceutical, pulp, paper production, and wastewater treatment.

• Welding of alloy C-276 and similar composition steels

• Dissimilar joints between nickel alloys, stainless and low alloy steels

• Die plates, forge dies, hot shear blades, mandrel punches for hot working

• Suitable for joining ASTM B574, B575, B619, B622, B628 to itself, to steel, to other Ni-based alloys

• Application in chemical plants with highly corrosive conditions

|

Condition |

Tensile strength Mpa (Ksi) |

Yield strength Mpa (Ksi) |

Elongation % |

|

AWS Reaulrement |

690(100) |

Not specified |

Not specified |

|

Typical Results as weled |

730 (106) |

540 (79) |

39 |

_副本.jpg?x-oss-process=image/resize)

_副本.jpg)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.png?x-oss-process=image/resize,w_100/quality,q_100)