WL ERNiFeCr-2

WL ERNiFeCr-2

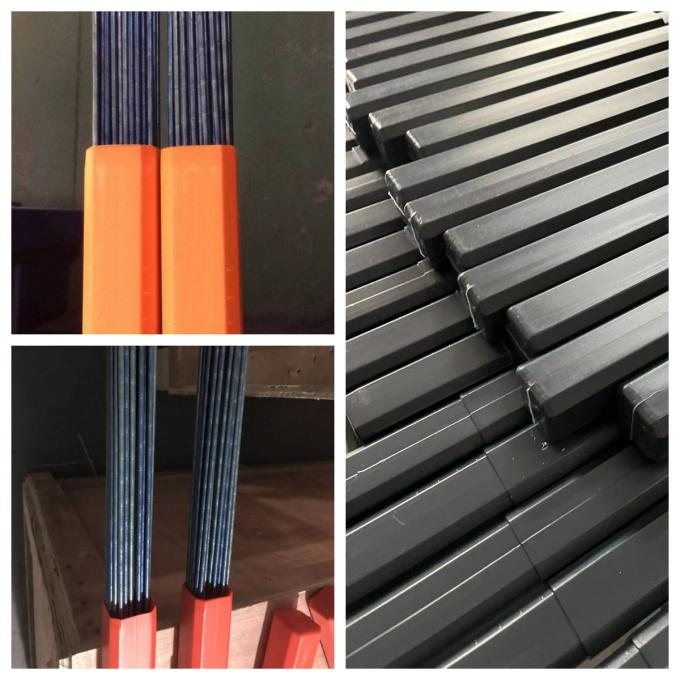

WL ERNiFeCr-2 Welding Rod - Nickel Based Alloy Hard Facing Rod Food aircraft high strength components

Properties: High resistance, high temperature resistance, corrosion resistance, wear resistance, fatigue resistance

Application: Primarily for welding aircraft high strength components and liquid rocket components exposed to cryogenic temperatures.

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

ERNiFeCr-2 is used for gas-tungsten-arc welding of alloys 718, 706 and X-750. The weld metal is age hardenable and has mechanical properties comparable to those of the base metals. The filler metal can be used with both the gas metal arc and gas tungsten arc processes.

|

Ni |

C |

P |

Fe |

Mn |

S |

Si |

Cu |

Al |

Ti |

Cr |

Co |

Mo |

B |

Other |

|

|

min |

50.0 |

|

|

Rem |

|

|

|

|

0.2 |

0.65 |

17.0 |

|

2.8 |

|

|

|

max |

55.0 |

0.08 |

0.015 |

0.35 |

0.015 |

0.35 |

0.3 |

0.8 |

1.15 |

21.0 |

1.0 |

3.3 |

0.006 |

0.5 |

AWS/ASME 5.14 ; AWS ERNiFeCr-2 ; UNS N07718

For length 350mm 500mm pack in carton each 5kg

For 1000mm packing in 5kg tube, 4 tubes in one 20kg carton

For length more than 1000mm, pack in wooden box directly

Primarily for welding aircraft high strength components and liquid rocket components exposed to cryogenic temperatures.

• It has good tensile strength, fatigue strength, creep fracture strength and other mechanical properties.

• It has high resistance to stress corrosion cracking of chloride and sulfide.

• MIG and TIG welding is not affected by temperature

• It has good welding characteristics

|

Tensile Strength Mpa(Psi) |

Elongation |

Density g/cm3 |

Melting Point ℃ |

Electrical Resistivity μΩ-m |

|

1138(165,000 ) |

25-30% |

8.19 g/cm3 |

1260-1335℃ |

1.3 |

_副本.jpg?x-oss-process=image/resize)

_副本.jpg)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.png?x-oss-process=image/resize,w_100/quality,q_100)