WL ERNiFeCr-1

WL ERNiFeCr-1

WL ERNiFeCr-1 Welding Rod - Nickel Based Alloy welding of nickel-chromium-molybdenum-copper alloys

Properties: Resistant to strong corrosion, stress corrosion cracking, pitting and crevice corrosion

Application: Nickel-chromium-molybdenum-copper alloys.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

ERNiFeCr-1 is used for TIG or MIG welding of Incoloy 825 and other nickel-chromium-molybdenum-copper alloys. Incoloy Filler Metal 65 can be also used to overlay cladding where similar chemical composition is required.

|

Ni |

C |

P |

Fe |

Mn |

S |

Si |

Cu |

Al |

Ti |

Cr |

Mo |

|

|

min |

38.0 |

|

|

22.0 |

|

|

|

1.5 |

|

0.6 |

19.5 |

2.5 |

|

max |

46.0 |

0.05 |

0.015 |

|

1 |

0.03 |

0.5 |

3.0 |

0.2 |

1.2 |

23.5 |

3.5 |

AWS A5.14 ERNiFeCr-1 ; SFA-5.14 ERNiFeCr-1 ; ASME IX, F-No.45 ; BS 2901NA41 ; (EN) ISO 18274 - SNi8065E(NiFe30Cr21Mo3)

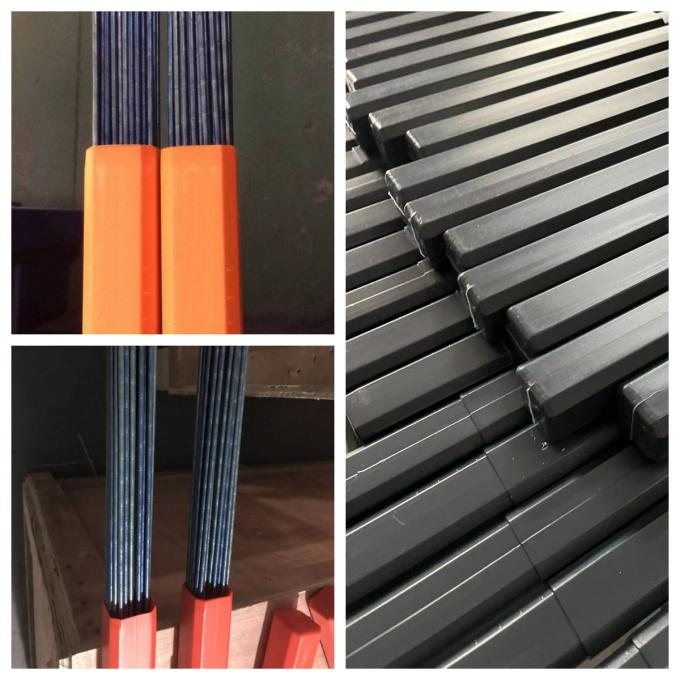

For length 350mm 500mm pack in carton each 5kg

For 1000mm packing in 5kg tube, 4 tubes in one 20kg carton

For length more than 1000mm, pack in wooden box directly

Used for welding of nickel-chromium-molybdenum-copper alloys.

• Used for welding of nickel-chromium-molybdenum-copper alloys.

• Also can be used to overlay cladding where similar chemical composition is required.

|

Condition |

Tensile strength Mpa (Ksi) |

Yield strength Mpa (Ksi) |

Elongation % |

|

AWS Reaulrement |

550 (80) |

Not specified |

Not specified |

|

Typical Results as weled |

550 (80) |

|

25 |

.jpg?x-oss-process=image/resize)

.jpg)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.png?x-oss-process=image/resize,w_100/quality,q_100)