WL ERNiCrMo-10

WL ERNiCrMo-10

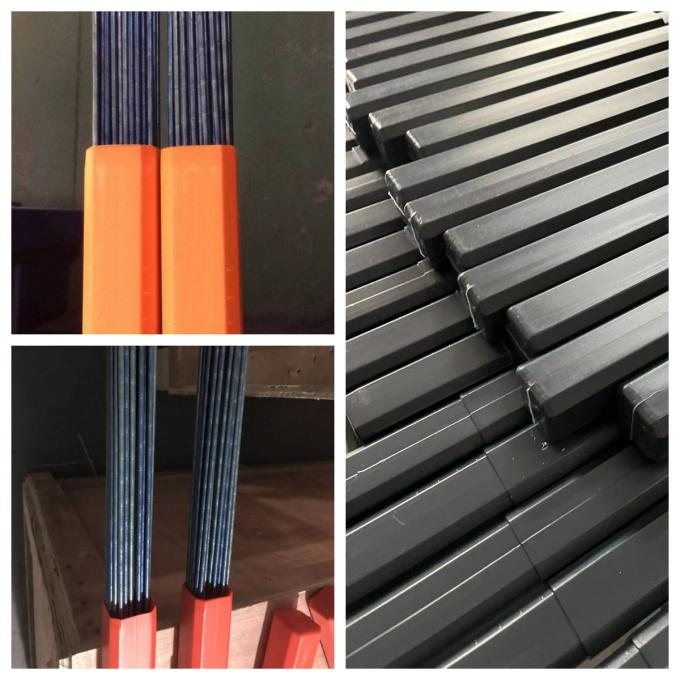

WL ERNiCrMo-10 Welding Rod - Nickel Based Alloy Boiler & pressure containers

Properties: Resistant to wear, corrosion and high temperatures

Application: Corrosion resistance, high temperature strength and creep resistance

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Alloy 622 is an alloy of nickel with chromium, molybdenum, and tungsten as the primary element of alloying. This wire is utilized to weld alloys of identical composition and different joints between nickel-chromium-molybdenum alloys and stainless steel or carbon or low alloys steels. It can even be used for cladding transferring as well as spraying applications.

|

Ni |

C |

P |

Fe |

Mn |

S |

Si |

Co |

V |

W |

Cr |

Mo |

Cu |

Other |

|

|

min |

Rem |

|

|

2.0 |

|

|

|

|

|

2.5 |

20.0 |

2.5 |

|

|

|

max |

0.015 |

0.02 |

6.0 |

0.5 |

0.01 |

0.08 |

2.5 |

0.35 |

3.5 |

22.5 |

3.5 |

0.5 |

0.5 |

AWS/ASME SFA 5.14 ; ERNiCrMo-10 ; UNS NO06022

For length 350mm 500mm pack in carton each 5kg

For 1000mm packing in 5kg tube, 4 tubes in one 20kg carton

For length more than 1000mm, pack in wooden box directly

• Marine engineering

• Furnaces & gas turbines

• Chemical manufacturing plants

• Boiler & pressure containers

• A nickel based alloy with chromium, molybdenum, and tungsten as the principal alloying elements.

• Used to weld alloys of similar composition as well as dissimilar joints between nickel-chromium-molybdenum alloys and stainless or carbon or low alloy steels.

• For cladding overlay as well as thermal spray applications.

• It offers an outstanding resistance to stress corrosion cracking, pitting and crevice corrosion.

|

Condition |

Tensile strength Mpa (Ksi) |

Yield strength Mpa (Ksi) |

Elongation % |

|

AWS Reaulrement |

690 (100) |

Not specified |

Not specified |

|

Typical Results as weled |

790 (115) |

570 (82) |

38 |

.jpg?x-oss-process=image/resize)

.jpg)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

_副本.png?x-oss-process=image/resize,w_100/quality,q_100)