WL Incoloy 925

WL Incoloy 925

INCOLOY alloy 925 N09925 used for down-hole and surface gaswell components

INCOLOY® alloy 925 (UNS N09925) is an agehardenable nickel-iron-chromium alloy with additions of molybdenum, copper, titanium and aluminum. The alloy’s chemical composition is designed to provide a combination of high strength and excellent corrosion resistance. The nickel content is sufficient for protection against chloride-ion stresscorrosion cracking. The nickel, in conjunction with the molybdenum and copper, also gives outstanding resistance to reducing chemicals. The molybdenum aids resistance to pitting and crevice corrosion. The alloy’s chromium content provides resistance to oxidizing environments. The titanium and aluminum additions cause a strengthening reaction during heat treatment.

INCOLOY alloy 925 is used in various applications requiring a combination of high strength and corrosion resistance. Because of the alloy’s resistance to sulfide stress cracking and stress-corrosion cracking in “sour” (H2S containing) crude oil and natural gas, it is used for down-hole and surface gaswell components including tubular products, valves, hangers, landing nipples, tool joints and packers. The alloy is also useful for fasteners, marine and pump shafting and high-strength piping systems.

|

GB |

UNS |

DIN |

W-Nr. |

BS |

|

NS1402 |

N09925 |

NiCr21Mo |

2.4858 |

NA16 |

|

% |

Ni |

Cr |

Fe |

Cu |

Mo |

Ti |

Al |

Mn |

Si |

C |

S |

Nb |

|

Min |

42.0 |

19.5 |

22.0 |

1.5 |

2.5 |

1.9 |

0.1 |

|

|

|

|

|

|

Max |

46.0 |

22.5 |

|

3.0 |

3.5 |

2.4 |

0.5 |

1.0 |

0.5 |

0.03 |

0.03 |

0.5 |

|

Grade |

Density |

Melting Point |

Tensile strength,MPa |

Yield strength,MPa |

Elongation,% |

|

Incoloy 925 |

8.08g/cm3 |

1311°C-1366 °C |

1210 |

810 |

24 |

Used for surface and down-hole hardware in sour gas wells and for oil-production equipment.

The alloy has outstanding resistance to general corrosion, pitting, crevice corrosion and stress-corrosion cracking in many aqueous environments, including those containing sulfides and chiorides.

|

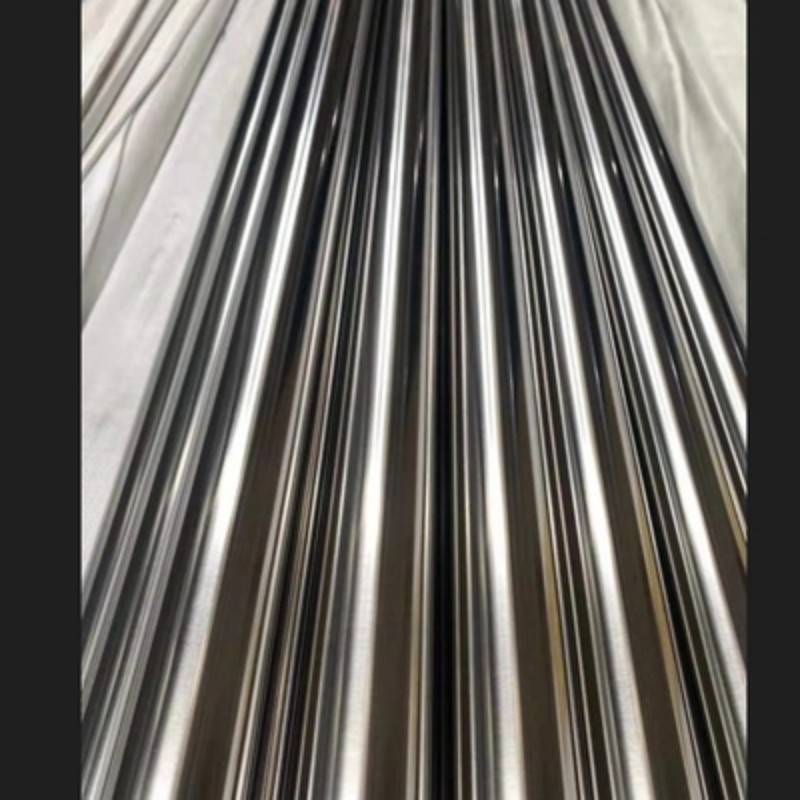

Rod, Bar |

Pipe, Tube |

Plate, Sheet, Strip |

Pipe fittings |

Forgings |

Wire |

|

STM B425 |

ASTM B163.B423 |

ASTM B424 |

ASTM B366 |

ASTM B564 |

DIN 17753 |

_副本.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)